OCIM Welding Co., Ltd.

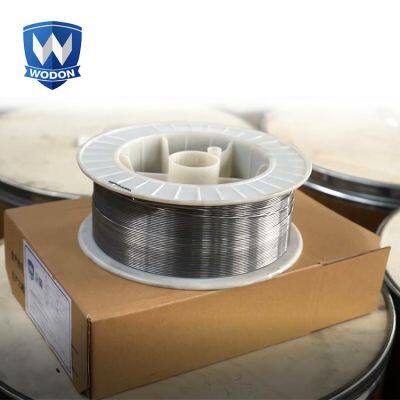

Main Products: Welding Wire, Welding Torch, Welding Accessories, Welding Helmet, Wire Feeder

Home > Company Introduction

Company Overview

We are one of leading manufacturer and trading company of welding wire, welding torches and parts, spool gun, welding helmet, tungsten electrode, welding machines and relevant products.

With professional technicians and good service, as a reliable supplier and exporter, we are seeking for more channels of cooperation with overseas clients. If you are interested in our products or services, please feel free to contact us.

Note: All names and trademarks listed herein are the property of their respective manufacturers, all parts are not original, References to the original part numbers are for your convenience only.

-

Trading CompanyBusiness Type

-

2010Year Established

-

Below 1,000 square metersFactory Size

-

101 - 200 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

101 - 200 People Total Employees

-

Southern Europe, Central America, Oceania, Africa, Western Europe, Eastern Europe, South America, North America, Eastern Asia, Northern Europe, Mid East, Southeast Asia Main Markets

-

ShangHai, Guangzhou, Ningbo Port of Shipment

-

Other Welding & Soldering Supplies Main Industry

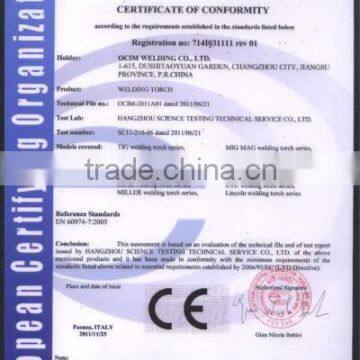

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.